SV R

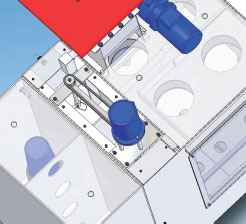

Development and reclaiming manual cabin with close loop

FEATURES

SV-R model is an accessory that has become indispensable in silk screen sector. Indeed, the more that of a normal bathtub for the development and the recovery of the frames, it is a system that guarantees to printers to work with recirculated water..

It drastically decreases costs related to the disposal of waste water. In this regard, the most comprehensive, SV-R FLOK CC which gives the operator the possibility to develop or recover, piling up the dirty water in storage tanks or reservoirs integrated into the flocculation system ECOWATER.

ECOWATER, thanks to a chemical-physical process, clarifies the water and reuse it later (maximum volume 600 l / h).

In order to ensure adequate autonomy, a second tank “C2” is connected so that it can receive flocculated clean water. An additional tank “C3” is dedicated to the disposal of the water no longer cleanable, positioned between the first tank “C1 ” and the flocculation system. ECOWATER, integrated separately to any PVC cabin, already existing to any customer, can work independently to regenerate the water used by the operator, in order to reuse the same, many times before disposal. Thanks to a special chemical formulation, the powder reacts with water creating flocs of dirt which will then be separated through the use of filter bags, easily replaceable.

It is evident the saving in terms of quantity, which concerns the disposal. In the SV version FLOK Standard, there are no storage tanks, but tanks of 300 l. (80 US gals) places under the cabin PVC and next to the ECOWATER. The amount of water available is less, but allows to recover useful space for those users who do not have the availability of space and a number of frames to be treated.